|

Rheology BulletinVol. 68, No. 1 (January 1999)Rakesh Gupta, Editor |

|

Rheology BulletinVol. 68, No. 1 (January 1999)Rakesh Gupta, Editor |

[Rheology Bulletin Home Page][Recent Issues]

ContentsExecutive Committee - 1997-99

Committees

Rheology Short CourseA two-day short course on Optical Rheometry will be offered in Madison, October 16-17, 1999. Course content includes an introduction to the physics of light propagation, optical methods, molecular models of optical properties, the design of optical experiments, and applications. The instructor is Professor G.G. Fuller of Stanford University. Additional details are available at the Society web site. A complete description and registration information will be included in the July 1999 issue of the Rheology Bulletin.71st Annual Meeting

The 1999 annual meeting of The Society of Rheology will be held

at the Monona Terrace Convention Center in Madison, Wisconsin. The meeting organizers are:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Technical Program Chairs | ||

| Prof. Robert C. Armstrong Dept. of Chemical Engineering Massachusetts Institute of Technology 77 Massachusetts Avenue, MIT 66-350 Cambridge, MA 02139-4307 (617) 253-4581; Fax: (617) 258-8992 E-mail: rca@mit.edu |

Prof. Daniel J. Klingenberg Dept. of Chemical Engineering University of Wisconsin 1415 Engineering Drive Madison, WI 53706-1691 (608) 262-8932; Fax: (608) 262-5434 E-mail: klingen@engr.wisc.edu |

|

| Local Arrangement Chair | ||

| Prof. A. Jeffrey Giacomin Chair, Rheology Research Center University of Wisconsin 309 Mechanical Engineering Building 1513 University Avenue Madison, WI 53706-1572 (608) 262-7473; Fax: (608) 265-2316 e-mail: giacomin@engr.wisc.edu |

||

The Dane County Regional Airport offers service via a number of major airlines. Transportation from the airport is available through hotel shuttles, or city limo and taxi service. An alternative is to fly to O’Hare in Chicago and take the Van Gelder Bus directly from O’Hare airport (International Terminal # 5, lower level, exit 5E) to Madison. The bus runs almost hourly and tickets ($18) can be purchased on board the bus. Additionally, interstate highways I-90 and I-94 intersect at Madison and provide easy access from Chicago, Milwaukee, and Minneapolis.

The annual meeting of The Society of Rheology will be held at the new Frank Lloyd Wright-designed Monona Terrace Convention Center, located two blocks from the State Capitol on the shores of Lake Monona. Originally proposed in 1938, this Convention Center brings to life one of Wright’s final creative visions in a spectacular lakeside setting.

October in Madison is prime time for visitors. In fact, October 15-16, will be the University of Wisconsin Football Homecoming weekend. Early travel and lodging arrangements are advised.

Registration and housing forms, and other information on the Madison meeting will be included in the July Bulletin and is available at this web site.

Authors wishing to present a paper in Madison should submit an abstract by May 9, 1999. The preferred medium for submitting the abstract is through the World Wide Web using the SoR abstract submission page at http://www.umche.maine.edu/sor/.

Otherwise, an abstract form may be requested from

| Ms. Janis Bennett c/o American Institute of Physics 500 Sunnyside Boulevard Woodbury, NY 11797 Tel: (516) 576-2403 Fax: (516) 576-2223 |

or downloaded from the SoR web site. The completed form should be returned to either of the technical program chairs, with a copy to the appropriate symposium chair. The planned symposia are:

| 1. Viscoelasticity of Synthethic and Biological Polymer Solutions and Gels | ||

| Special Symposium in Honor of John Ferry | ||

| Ralph H. Colby Department of Materials Science and Engineering The Pennsylvania State University University Park, PA 16802 814-863-3457; 814-865-2917 (fax) E-mail: rhc@plmsc.psu.edu |

Donald J. Plazek Mat. Sci. & Engr. Dept., 848 BEH University of Pittsburgh Pittsburgh, PA 15261 412-624-7864; 412-624-8069 (fax) E-mail: plazek@engrng.pitt.edu |

|

| Guy C. Berry Department of Chemistry Carnegie Mellon University 4400 Fifth Ave. Pittsburgh, PA 15213 412-268-3131; 412-268-6897 (fax) E-mail: gcberry@andrew.cmu.edu |

||

| 2. Rheology of Polymer Melts and Solutions | ||

| Examples: experimental methods, associating polymers, polyelectrolytes | ||

| John L. Schrag Department of Chemistry University of Wisconsin 1101 University Avenue Madison, WI 53706 608-262-0453 (fax) E-mail: schrag@chem.wisc.edu |

Faith Morrison Department of Chemical Engineering Michigan Technological University 1400 Townsend Drive Houghton, MI 49931-1295 906-487-2050; 906-487-3132 (fax) E-mail: fmorriso@mtu.edu |

|

| 3. Liquid Crystals and Liquid Crystialline Polymers | ||

| Examples: coupling flow and order, phase transitions, structure-property relations | ||

| Julie Kornfield Chemical Engineering 210-41 California Institute of Technology Pasadena, CA 91125 626-395-4138/4637; 626-568-8743 (fax) E-mail: jak@cheme.caltech.edu |

Jan W. van Egmond Union Carbide Corporation P. O. Box 8361 South Charleston, WV 25303 304-344-5008, 304-747-3928 (fax) E-mail: vanegjw@ucarb.com |

|

| Jimmy Jingtao Feng Levich Institute, Steinman Hall #1M City College of CUNY 140th Street & Convent Avenue New York, NY 10031-9198 212-650-6844; 212-650-6835 (fax) E-mail: feng@lisgi1.engr.ccny.cuny.edu |

||

| 4. Blends and Block Copolymers | ||

| Examples: shear-induced structure, novel architectures, phase separation, structure-property relations | ||

| Timothy P. Lodge Department of Chemistry and Department of Chemical Engineering & Material Science Institute of Technology University of Minnesota 235 Smith Hall 207 Pleasant Street S. E. Minneapolis, MN 55455-0431 612-625-0877; 612-624-1589 (fax) E-mail: lodge@chem.umn.edu |

Paula Moldanaers Department of Chemical Engineering K. U. Leuven de Croylaan 46 B-3001 Leuven-Heverlee Belgium 32-16-322359; 32-16-322991 (fax) E-mail: paula.moldenaers@cit.kuleuven.ac.be |

|

| 5. Rheology of Solids | ||

| Examples: constitutive equations, composites, aging, structure-property relations | ||

| Alan Wineman Dept. of Mechanical Engineering and Applied Mathematics University of Michigan Ann Arbor, MI 48109 734-936-0411; 734-764-4256 (fax) E-mail: lardan@engin.umich.edu |

Roderic S. Lakes Deparment of Engineering Physics University of Wisconsin 1500 Engineering Drive Madison, WI 53706 608-265-8697; 608-263-7451 (fax) E-mail: lakes@engr.wisc.edu |

|

| 6. Shear-free Flows | ||

| Examples: elongational and extensional flows, experimental methods | ||

| John Wiest Chemical Engineering Department Box 870203 University of Alabama Tuscaloosa, AL 35487 205-348-1727; 205-348-7558 (fax) E-mail: jwiest@coe.eng.ua.edu |

Kurt W. Koelling Dept. of Chemical Engineering The Ohio State University 140 W. 19th Ave. Columbus, OH 43210-1180 614-292-2256; 614-292-9271 (fax) E-mail: koelling.1@osu.edu |

|

| David James Department of Mechanical and Industrial Engineeering University of Toronto Toronto, Canada M5S 3G8 416-978-3049; 416-978-7753 (fax) E-mail: david.james@utoronto.ca |

||

| 7. Non-Newtonian Fluid Mechanics | ||

| Examples: experimental, analytical, and numerical studies of complex flows, connections with molecular or microstructural models, stability, flow transitions | ||

| Michael D. Graham Department of Chemical Engineering University of Wisconsin 1415 Engineering Drive Madison, WI 53706 608-265-3780; 608-262-5434 (fax) E-mail: graham@engr.wisc.edu |

Radhakrishna Sureshkumar Campus Box 1198 Department of Chemical Engineering Washington University St. Louis, MO 63130 314-935-4988; 314-935-7211 (fax) E-mail: suresh@poly1.wustl.edu |

|

| Lars Genieser Union Carbide Corporation P. O. Box 670 Bldg. 98, Room 480 Bound Brook, NJ 08805-0670 732-563-5627; 732-563-5603 (fax) E-mail: lhgenies@bellatlantic.net |

||

| 8. Heterogeneous Systems | ||

| Examples: suspensions, colloidal dispersions, emulsions, electro- and magnetorheological fluids | ||

| Daniel De Kee Department of Chemical Engineering Tulane University New Orleans, LA 70118-5674 504-865-5620; 504-865-6744 (fax) E-mail: ddekee@mailhost.tcs.tulane.edu |

Lisa Mondy Energetic and Multiphase Processes Department Sandia National Laboratories Albuquerque, NM 87185-0834 505-844-1755; 505-844-8251 (fax) E-mail: lamondy@sandia.gov |

|

| Mike Solomon Department of Chemical Engineering Univeristy of Michigan - Ann Arbor 3142 H. H. Dow Bldg., 2300 Hayward St. Ann Arbor, MI 48109-2136 734-764-3119; 734-763-0459 (fax) E-mail: mjsolo@umich.edu |

||

| 9. Industrial Rheology | ||

| Examples: fiber and film processing, instabilities in polymer processing, rheology of commercial fluids (e.g., cosmetics, paints, coating fluids), extrusion, injection molding and mixing | ||

| Chris E. Scott Department of Materials Science and Engineering Massachusetts Institute of Technology MIT Room 13-5013 77 Massachusetts Avenue Cambridge, MA 02139 617-258-6133; 617-253-6896 (fax) E-mail: cscott@mit.edu |

Roger A. Ross DuPont Nylon Fiber Engineering Technology Center 4501 N. Access Rd. Chattanooga, TN 37415-3899 432-875-7780; 432-875-7551 (fax) E-mail: roger.a.ross@usa.dupont.com |

|

| William H. Tuminello The DuPont Company The Experimental Station P. O. Box 80536 Wilmington, DE 19980-0356 302-695-7330; 302-695-8120 (fax) E-mail: william.h.tuminello@usa.dupont.com |

||

| 10. General Session | ||

| Dave S. Malkus Department of Engineering Physics (EMA Program) University of Wisconsin 1500 Engineering Drive Madison, WI 53706 608-262-4515; 608-263-7451 (fax) E-mail: malkus@cms.wisc.edu |

Donald G. Baird Department of Chemical Engineering Virginia Tech Blacksburg, VA 24061-0211 540-231-5998; 540-231-2732 (fax) E-mail: dbaird@vt.edu |

|

The winners of the 1998 Journal of Rheology Publication Award are Michael J. MacDonald and Susan J. Muller for "Experimental study of shear-induced migration of polymers in dilute solution," Journal of Rheology, 40, 259-283 (1996).

The Society of Rheology is again offering grants to support the cost of public transportation to the annual meeting of the Society to graduate student members of the Society. Details concerning eligibility, application procedure and application deadline may be found on the web page of the Society or by contacting Professor Don Baird of the Department of Chemical Engineering at Virginia Tech. He may be reached by phone at (540) 231-5998 or by e-mail at dbaird@vt.edu.

| Robert C. Armstrong, chair Department of Chemical Engineering Massachusetts Institute of Technology Cambridge, MA 02139 (617) 253-4581; Fax: (617) 258-8992 rca@mit.edu |

| John F. Brady Department of Chemical Engineering California Institute of Technology Pasadena, CA 91125 (626) 395-4183; Fax: (626) 568-8743 jfb@caltech.edu |

| Robert Secor 3M Engineering Systems and Technology 3M Center, Building 518-1-01 St. Paul, MN 55144 (612) 733-0864; Fax: (612) 736-3122 rbsecor@mmm.com |

P. Dontula and C. W. Macosko

Coating Process Fundamentals Program

Center for Interfacial Engineering and

Department of Chemical Engineering & Materials Science

University of Minnesota

Minneapolis, MN 55455

(See erratum of this paper.)

At the 22nd annual short course on rheological measurements at the University of Minnesota in August 1997, two enthusiastic participants presented the instructors with an interesting problem: how do gel-like particles, some as large as 5 mm in diameter, remain suspended in the commercially available Orbitz™ drink? The results of a few rheological measurements reported here serve as a useful pedagogical tool. We have in fact used the ideas presented here as a home exercise in one of our courses, titled Principles and Applications of Rheology. We have also learned that Professor Larson has used this sample at the University of Michigan as a teaching example.

|

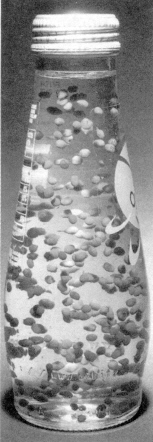

| Figure 1. The commercially available Orbitz™. |

The overall appearance of Orbitz™ (Figure 1, Clearly Canadian Beverage Corp., Vancouver, Canada) is striking: the suspension is stable to violent agitation, but millimeter-size air bubbles entrained during agitation rise to the surface within seconds; a small angular displacement imparted to the liquid in the container moves the particles, but they recoil and even overshoot their initial positions and execute damped oscillations; and yet, the liquid appears to have the consistency of water. In the absence of other effects, large particles such as these will remain suspended only if the densities of the liquid and the particles are identical. All of these features suggest a complex rheological behavior and an excellent example for analysis.

Rheological properties of the supernatant liquid in Orbitz™ were measured at 20 °C with a controlled-strain rheometer (RFS-II) and a controlled-stress rheometer (SR-2000), both manufactured by Rheometric Scientific, Piscataway, NJ. Concentric cylinders, or Couette, fixtures (32 mm inner cylinder diameter, 1 mm radial gap and 33 mm length in the RFS-II, and 29.5 mm inner cylinder diameter, 1.25 mm radial gap and 44.25 mm length in the SR-2000) maximized the torque signal. Water-soaked foam-lined covers minimized water loss by evaporation. The linear viscoelastic strain limit of the liquid determined by small amplitude oscillatory measurements (at 1 s-1) was between 15% and 20%. Repeat measurements without any delay between experiments resulted in lower observed values of the elastic modulus, but those after a 5 min delay showed that the modulus had completely recovered to its original value, indicating a strain-sensitive structure in the liquid. Oscillatory measurements performed with and without pre-shearing the liquid are compared in Figure 2a. The frequency was stepped down from 100 s-1 to 0.1 s-1 in both experiments, and a 10% strain was imposed. Liquid inertia limited the highest frequency at which phase angles were accurately determined to about 30 s-1. The elastic modulus G' falls with frequency, and plateaus at about 0.13 Pa. The values of G' after pre-shearing were consistently smaller than without pre-shearing, and rose with frequency below 1 s-1. Because frequency sweeps take a few minutes to complete and impose small strain, the disrupted structure in the liquid may recover during the experiment. This is demonstrated in Figure 2b which traces the rise in G' with time after pre-shearing. The elastic modulus rose to about 90% of the value in Figure 2a in 7 min after shearing was stopped.

|

| (a) |

|

| (b) |

| Figure 2. Elastic and viscous moduli of the supernatant liquid. (a) Versus frequency, with and without pre-shearing. (b) Versus time, after pre-shearing. The frequency was 1 s-1, and the strain imposed was 10%. |

Shear viscosity of the supernatant liquid was measured by two different experiments: "instantaneous" step-rate experiments, in which the velocity of the rotating cylinder was quickly raised to its programmed value on the controlled-strain rheometer, and creep experiments on the controlled-stress rheometer. Viscosity falls sharply with rising shear rate, and values from both experiments show reasonable agreement (Figure 3a). The shear viscosity is only four times that of water at 100 s-1, explaining the fluidity of the sample at first sight. Viscosity replotted versus shear stress (Figure 3b) shows a sharp drop at a stress between 0.03 and 0.04 Pa. There are two critical stress levels, one around 0.04 Pa and the other around 0.075 Pa, in the measurements taken with the controlled-strain rheometer. This may be because stress in the liquid immediately adjacent to the moving member in the controlled-strain rheometer rises sharply at start-up and then falls to the measured value as the velocity profile develops. If the stress exceeds the yield stress, the liquid adjacent to the moving wall will yield. Then, the steady-state velocity profile and the time to attain it will depend on the shear rate and the rate of formation of the structure in the liquid, and may be quite complex. In contrast, during the creep experiment, the stress in the liquid never exceeds the programmed stress. Hence, the yield stress is more accurately determined by creep experiments. The yield stress t of 0.04 Pa obtained in creep measurements compares favorably with 0.045 Pa obtained from oscillatory experiments in which the strain was raised in steps from 0.1% to 100% at a frequency of 5 s-1. The yield stress is sometimes estimated as G*g, where G* is the complex modulus at the linear viscoelastic strain limit g. The yield stress t of 0.04 Pa is roughly twice that used to suspend insoluble "builder" particles in liquid detergents (Barnes, 1980).

|

| (a) |

|

| (b) |

| Figure 3. Shear viscosity of the supernatant liquid in Orbitz™ versus (a) shear rate, and the same data replotted versus (b) shear stress. Couette fixtures were used in both the rheometers. When the inner cylinder rotates and the shear rates exceed 500 s-1, the critical Taylor number for the onset of vortices in the annular gap is exceeded; the ensuing secondary flow may raise the apparent viscosity. |

A balance between the buoyant (or gravitational) force, 4 Dr p R3/3, and the restoring force due to the yield stress in the liquid, t p R2, provides an estimate of the minimum (or maximum) density of a spherical particle of radius R that will remain motionless in the liquid. Here, Dr is the absolute value of the difference in densities of the liquid and the particles. With particles of 5 mm in diameter, the maximum density difference that can be supported by the Orbitz™ liquid is about 12 kg/m3. This is easily attained in practice if the particles are swollen in solution, as is the case with Orbitz™. Air bubbles smaller than about 60 mm in diameter can be expected to remain stationary in Orbitz™.

ACKNOWLEDGEMENTS

The authors thank Susan C. Forman, Hercules Inc., and Alan Graham, Los Alamos National Laboratories, for bringing Orbitz™ to their attention. P. Dontula was supported by industrial and National Science Foundation funds through the Center for Interfacial Engineering at the University of Minnesota.

REFERENCES

Barnes, H.A., "Detergents," in Rheometry: Industrial Applications, edited by K. Walters (Wiley, Chichester, U.K., 1980).

The Rheology Bulletin publishes papers on the applied aspects of Rheology which are intended for the non-specialist. Appropriate topics include the application of rheological principles to a specific system, instrumentation for rheological measurements, description of interesting rheological phenomena, and the use of well-established rheological techniques to characterize products, processes or phenomena. Papers describing historical aspects of the practice of rheology and how these have influenced current trends are welcome. Also welcome are papers that address the present and changing status of rheological education. Consultation with the Editor prior to manuscript submission is encouraged.

FLUID MECHANICS: AN INTERACTIVE TEXT

James A. Liggett and David A. Caughey

CD-ROM (1998); ISBN 0-7844-0310-4

$100/$75 Students and ASCE Members

ASCE Press, 1801 Alexander Bell Drive, Reston, VA 20191

Tel: (800) 548-2723

Fluid Mechanics: An Interactive Text integrates a multimedia presentation with the computational capabilities of MATLAB (The MathWorks) to provide an introduction for undergraduates. This software was developed with Authorware (Macromedia) and runs on PC (486/50 MHz, Windows 3.1, 95, NT) and Macintosh (68030 or PowerPC, System 7.5 or later) computers with minimal system requirements (4X CD-ROM, 16 MB RAM, 30 MB disk space, 640×480 screen resolution, 256 colors). The CD-ROM must be in the drive for the program to start. A table of contents was not provided with the enclosed documentation, so a listing is provided below.

Preface and Users Guide, Introduction, Basic Considerations, Fluid Statics, Integral Description, Dimensional Analysis and Similitude, Laminar and Turbulent Flows, Incompressible Pipe Flow, Potential Flow, Boundary Layers, Flow Past Bodies, Compressible Flows, Open Channel Flows, Fluid Machinery, Transport.

These chapters are typically divided into small sections which fit the presentation method and possibly the attention span of the intended audience. These sections provide a good overview of most subjects covered in a typical undergraduate course on fluid mechanics. The reader can set the presentation "Level" starting with an overview (Level 1), then adding quantitative information (Level 2) and finally specialized information (Level 3).

One advantage of an interactive text is rapid navigation of the material. Chapters are selected from the Table of Contents or using numbers at the bottom of the screen. Each chapter is loaded from the CD-ROM as requested by the user. However, this process is slow, inhibiting a reader’s ability to browse the text. A "word search" feature only works within the current chapter. A slide bar at the bottom of the screen and "Next", "Previous" and "Back" buttons provide navigation within a chapter. A "history list" provides access to any of the last 50 pages viewed by the reader. Screens can also be located using a "bookmark". Text in bold or colored font is linked to other screens including figures, graphs, equations and the glossary. This navigational feature is especially effective with equations, allowing a reader to view the referenced equation alone or in the context of a screen on which it appears. The "Table of Figures" and "Glossary Index" are also useful for jumping to a particular illustration of concept in the text. A "Figure Search" utility allows the reader to find animations, applications, figures, graphs, movies, photographs and tables using a text description.

Other advantages of an interactive text include annotation, visualization and computation capabilities. The reader can add "Notes" to a screen; the notes can be collected and saved as a text file for any chapter. The text also contains "Footnotes" inserted by the authors to expand on sentences marked by an asterisk in the text. Material cannot be copied from the text, but screens can be printed in landscape mode. Figures are displayed in "thumbnail" size but can be expanded by clicking on a "magnifying glass" icon. Some graphs and tables are directly accessible using the "Data" menu at the top of the screen. Animations and videos are launched using a "filmstrip" icon and controlled with arrow buttons at the bottom of the resulting frame. MATLAB enables a reader to interact with some graphs, tables and equations. This software is also used in a number of computational tools, which are launched using the "Tools" menu at the top of the screen. Descriptions of these tools are listed below:

These programs are documented in appendices at the end of some chapters. Additional documentation is available from the "Help" menu at the top of the screen.

Fluid Mechanics: An Interactive Text is a good overview of the subject for undergraduate students. The presentation implements useful navigational features with computational tools. I recommend purchase as a supplement to laboratory and lecture courses involving fluid mechanics.

| W.E. VanArsdale Department of Mechanical Engineering University of Houston Houston, TX 77204 |

| THE SOCIETY OF RHEOLOGY c/o American Institute of Physics 500 Sunnyside Boulevard Woodbury, NY 11797 |

[Rheology Bulletin Home Page][Recent Issues]

[/sor/mailto.htm] Updated 14 February 2010 |